Husky’s closure applications can improve the sustainability of your package through:

- Material Light-Weighting

- Migration to a new Neck Finish

- Use of Alternative Materials

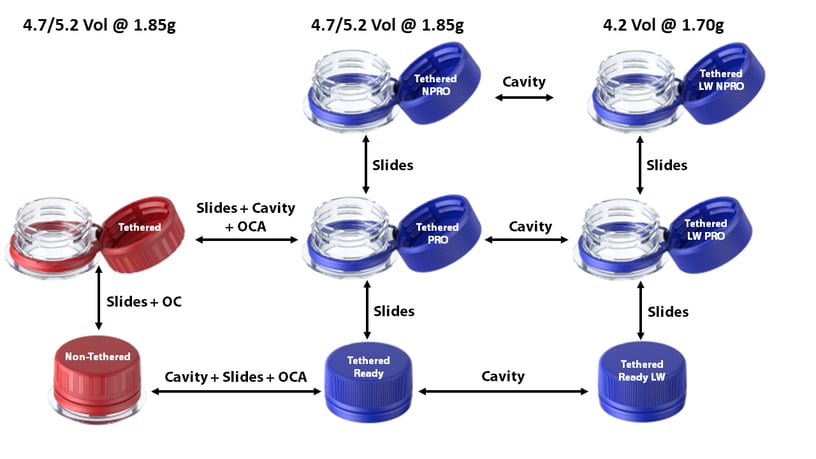

- Tethering

Material Light-Weighting

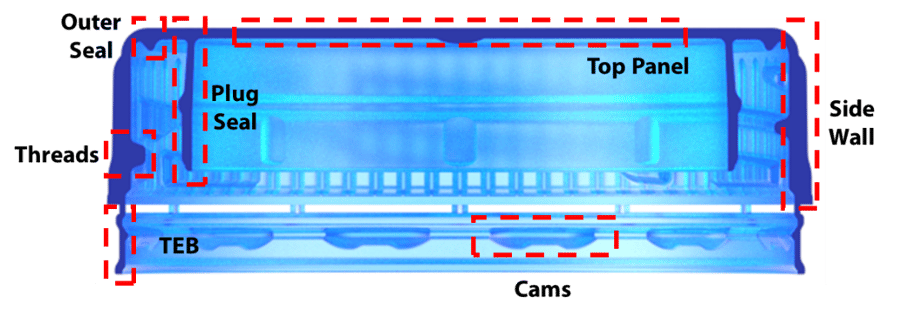

The Light-Weighting topic is straight-forward. Remove as much resin from specific closure features without negatively impacting performance or the user experience. A lower part weight lowers the raw material cost per piece and can enhance manufacturing productivity.

Migration to a new Neck Finish

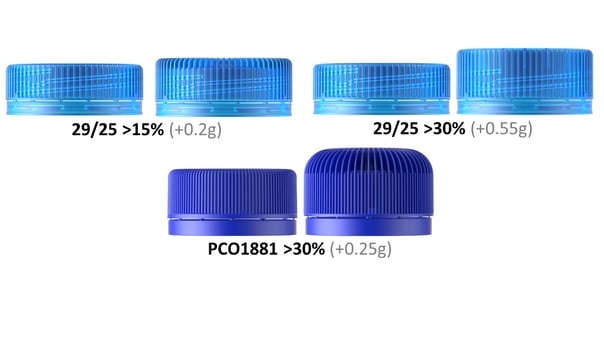

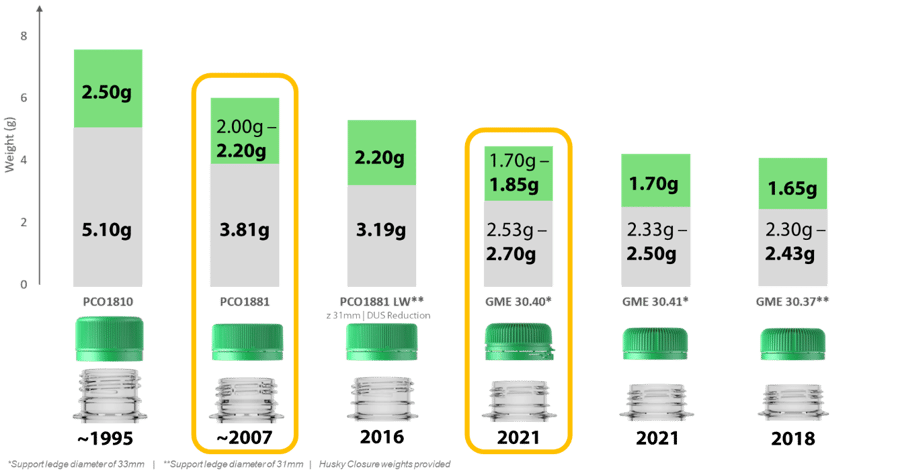

The introduction of new industry standard neck finishes can offer higher levels of performance at a lighter weight. The chart below highlights industry standard CSD neck finishes. The recently introduced GME30.40 neck finish offers a higher level of performance without compromising the user experience. Similar weight savings can be achieved in the Water, Juice, Sport Drink, and Tea markets.

Use of Alternative Materials

Increasing the use of PCR content is another means to support the improved sustainability of your closure design. The current challenge with this approach is the lack of availability of food grade PCR material. Closed loop recovery systems whereby the closures can be mechanically recycled within the same facility and reintroduced into the molding system is another way to improve the sustainability efforts.

Husky is also exploring the use of PET as a potential alternative resin for closure manufacture. While HDPE and PP are proven and fully recyclable materials for closures, there are some obvious benefits to using a single material for bottle and closures:

- Simplify the separation efforts at the recycling stage (bottle + closure are of the same material)

- Increase the quality/yield of the PET bales

- Increase the availability of rPET

- Unlock new possibilities for package differentiation

Some resin manufacturers are offering other sustainable choices like certified ocean bound material. This is PCR material that has been collected form the environment that was destined for the oceans. The appropriate remediation activities have been performed on this material to make it food grade approved.